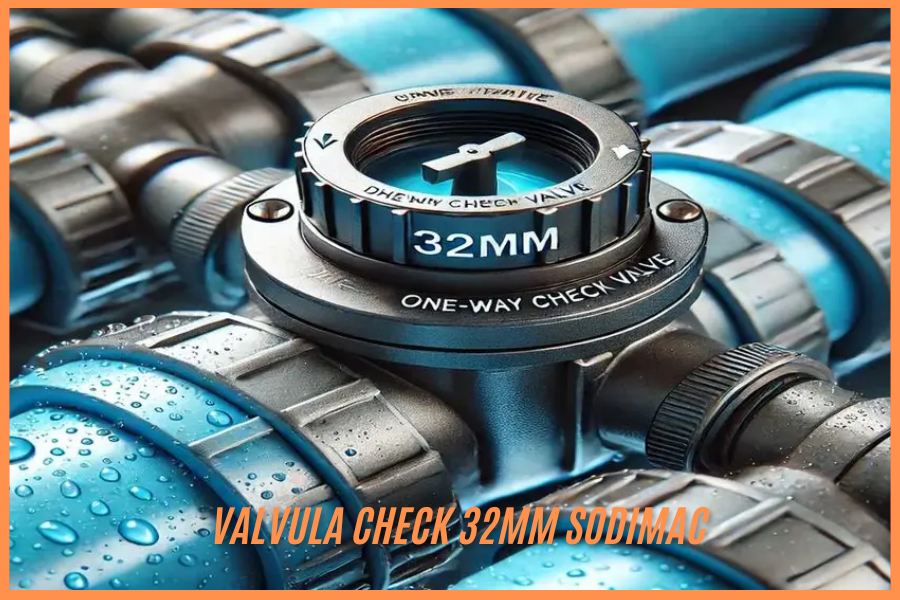

In the world of fluid control, one essential component that ensures the safety and efficiency of plumbing and industrial systems is the check valve. Among the many different sizes and types of check valves, the Valvula Check 32mm Sodimac out due to its versatile applications in residential, commercial, and industrial systems. But what exactly is a check valve, why is it important, and how do you go about selecting the right one for your system? Let’s take a deeper look into the specifics of the 32mm check valve.

What is a Check Valve?

A check valve is a one-way valve that allows the flow of fluids in a single direction. Its primary function is to prevent backflow — the unwanted reversal of fluid that can contaminate clean water supplies, damage systems, or cause operational failures. The check valve operates without the need for manual control, relying on the pressure of the incoming fluid to keep it open and allowing the fluid to pass through.

These valves are integral to various systems, whether in household plumbing, irrigation, or industrial processes. The role of a check valve is to maintain the proper direction of flow while ensuring that fluids can’t flow back into the system, preventing potential damage, contamination, or operational inefficiencies.

Wiki

| Attribute | Details |

| Product Name | Valvula Check 32mm Sodimac |

| Type | Check Valve |

| Size | 32mm |

| Function | Prevents backflow, ensures one-way fluid flow |

| Material Options | Bronze, Brass, Stainless Steel, PVC |

| Applications | Residential plumbing, irrigation, industrial systems |

| Pressure Rating | Varies based on material and application |

| Temperature Range | Varies based on material and system conditions |

| Connection Type | Threaded, flanged, or welded |

| Common Features | Backflow prevention, one-way flow, easy installation |

| Maintenance Requirements | Regular inspection, cleaning, and functional testing |

| Installation Location | Water supply lines, irrigation systems, industrial fluid systems |

| Brand | Sodimac |

| Availability | Available through Sodimac’s online store and retail locations |

| Price Range | Varies by material and application |

| Warranty | Typically offered by manufacturer or retailer |

The Importance of 32mm Check Valves

The 32mm check valve refers to a check valve that is designed to fit a 32mm pipe. This size is commonly used in small-scale systems like household water supply lines or irrigation systems, and its function is just as crucial in these contexts. A 32mm valve is compact enough to fit in these systems while offering the same backflow prevention as larger check valves used in more industrial applications.

For residential systems, where clean and uncontaminated water is paramount, a 32mm check valve ensures that the water remains safe, preventing any cross-contamination that may occur due to backflow. For irrigation systems, the valve helps keep the water flow steady and protects the water source from pollutants. In smaller industrial or commercial setups, these valves ensure fluid flows are maintained correctly, which is crucial for machinery efficiency and overall system performance.

Applications of 32mm Check Valves

A 32mm check valve is versatile and can be used across a range of applications. Below, we explore some of the common settings where these valves are utilized.

Residential Plumbing Systems

In homes, a 32mm check valve is often installed in water lines to prevent backflow from contaminating the drinking water supply. Backflow can occur due to sudden changes in water pressure, for example, when a pump is turned off or a nearby system malfunction occurs. In such cases, backflow may carry harmful substances into the water supply, which is not only dangerous but can be costly to remedy.

By installing a check valve in strategic locations (like at the water supply entry point), homeowners can prevent these issues, ensuring that water only flows in one direction and remains safe for use.

Irrigation Systems

In irrigation systems, 32mm check valves help regulate water flow and protect the system from backflow, which could contaminate water sources like wells or reservoirs. The proper direction of flow is crucial to ensure that water is used efficiently and that contaminants, fertilizers, or other chemicals used in irrigation don’t return to the water supply. These valves are commonly installed at various points along the system to maintain optimal operation and prevent damage to expensive irrigation equipment.

Industrial Applications

Smaller industrial systems that handle liquids or gases, such as chemical processing plants or water treatment facilities, often use 32mm check valves to ensure proper fluid direction. In these systems, the backflow of fluids could not only cause damage to pipes and equipment but could also lead to hazardous situations, especially when dealing with toxic or corrosive chemicals. The 32mm check valve serves as a safeguard against these risks.

For example, in water treatment, a check valve can prevent backflow from contaminating clean water after it has been filtered or treated. The valve ensures that any reverse flow is blocked, preserving the integrity of the system.

Materials Used in 32mm Check Valves

The material used for check valves is essential, as it determines the durability, corrosion resistance, and compatibility of the valve with different fluids. For a 32mm check valve, materials vary based on the intended use, fluid types, and environmental factors. Some common materials for check valves include:

Bronze

Bronze check valves are widely used due to their excellent corrosion resistance. This makes them ideal for water, steam, and other fluid systems where the valve may be exposed to harsh conditions. Bronze offers durability and reliability in residential plumbing systems where the need for corrosion resistance is high, such as in potable water systems.

Brass

Brass is another common material for check valves. It is often used in water systems because of its ability to resist corrosion while providing good strength and wear resistance. Brass check valves are a popular choice in plumbing systems, irrigation systems, and industrial applications where the valve needs to withstand moderate pressures without deteriorating.

Stainless Steel

For high-pressure and high-temperature applications, stainless steel check valves are often preferred. Stainless steel provides superior strength, resistance to corrosion, and durability in harsh environments. This makes it an excellent choice for more demanding applications, such as industrial and chemical processing systems. Stainless steel 32mm check valves are commonly found in systems where there is a need for extra toughness and longevity.

PVC (Polyvinyl Chloride)

In addition to metal materials, some 32mm check valves are made from PVC, especially in systems where low-cost, lightweight options are needed. PVC check valves are often used in irrigation systems or in environments where the fluid being transported is not highly corrosive. While not as durable as metals like bronze or stainless steel, PVC is an effective material for many standard applications.

Features of 32mm Check Valves

The selection of a 32mm check valve requires consideration of various features that will impact its performance, installation, and maintenance. Some key features to consider include:

Pressure Rating

One of the most important factors in selecting a check valve is its pressure rating. Check valves are rated for maximum pressure and must be chosen based on the specific pressure requirements of the system in which they will be installed. Selecting a valve with too low a pressure rating can lead to failure, leaks, or operational inefficiencies.

Temperature Range

Check valves are also rated for a particular temperature range. The materials used for the valve, as well as the design, will influence the valve’s ability to withstand high or low temperatures. For example, stainless steel check valves are often used in systems with high temperatures, whereas PVC check valves are better suited for lower temperatures.

Connection Type

Check valves come with different connection types to suit various plumbing and industrial systems. Some may have threaded connections, while others may have flanged or welded connections. The type of connection you choose will depend on the existing setup of the pipes in the system, ensuring that the valve can be properly installed and maintained.

Flow Characteristics

The flow characteristics of the valve determine how it will allow fluid to pass through. There are two main types of check valves commonly used:

- Swing Check Valve: In this type, a disc swings open to allow fluid to pass through and swings shut when flow stops or reverses, preventing backflow. Swing check valves are generally used for larger pipe sizes and lower velocity fluids.

- Lift Check Valve: This type uses a valve disc that lifts off a seat to allow flow in the correct direction and drops back down when the flow reverses. Lift check valves are more suited to systems with higher velocity and can handle higher pressures.

Installation and Maintenance of 32mm Check Valves

Proper installation and maintenance of 32mm check valves are crucial for ensuring their longevity and effectiveness. Here are some key considerations for both.

Installation

When installing a 32mm check valve, it’s essential to ensure that the valve is oriented correctly to allow for proper fluid flow. The valve should be installed in the direction indicated by the arrow on the valve body, which shows the proper direction of fluid flow. Incorrect installation could result in failure of the valve to function properly, leading to backflow and system issues.

Additionally, it is important to use the correct sealing materials during installation to prevent leaks. Proper alignment of pipes and valves is also necessary to avoid strain or stress on the valve that could lead to damage or malfunction.

Maintenance

Like any mechanical system, check valves require regular maintenance to ensure they continue to function correctly. This includes periodic inspections for signs of wear or corrosion, especially if the system is exposed to harsh chemicals or extreme temperatures. It’s also essential to clean the valve regularly to remove any debris or buildup that might hinder its operation.

Another key aspect of maintenance is functional testing. This involves checking that the valve opens and closes as required, without any sticking or leakage. Regular testing can help identify any issues early before they result in significant damage.

Troubleshooting Common Issues with 32mm Check Valves

Some common issues with check valves include:

- Leakage: Leaks can occur due to damaged seals or improper installation. Regular maintenance and inspection can prevent this issue.

- Sticking: Sticking is often caused by corrosion or debris buildup inside the valve. Cleaning and lubrication can help prevent sticking.

- Noise: A noisy check valve could indicate internal damage, improper flow, or an obstruction. Inspecting the valve and checking for any visible damage can help resolve this issue.

Conclusion

In conclusion, the valvula check 32mm Sodimac is an essential component in various fluid systems, offering reliable backflow prevention and ensuring the efficiency and safety of residential, commercial, and industrial applications. Whether for protecting water supply in homes, safeguarding irrigation systems, or optimizing industrial operations, this valve’s versatility and ease of use make it a must-have for any fluid control system. By choosing the right materials, considering the pressure and temperature requirements, and ensuring proper installation and maintenance, you can maximize the lifespan and performance of your valvula check 32mm Sodimac.

Make sure to carefully assess the needs of your system to select the perfect valve for your project, and rely on reputable sources like Sodimac for high-quality products that meet your expectations.

FAQs

1. What is a “valvula check 32mm Sodimac”?

A “valvula check 32mm Sodimac” is a 32mm check valve available through Sodimac, a renowned supplier of plumbing and industrial products. It functions to allow fluid to flow in only one direction, preventing backflow and potential damage to systems.

2. Why is backflow prevention important in plumbing systems?

Backflow prevention is critical to avoid the contamination of potable water systems, which could occur if water reverses direction and picks up harmful contaminants. Installing a check valve, like the valvula check 32mm Sodimac, ensures that water flows safely and securely in one direction, preserving water quality.

3. How do I install a 32mm check valve?

To install a valvula check 32mm Sodimac, ensure the valve is oriented in the correct direction as indicated by the flow arrow on the valve body. Proper sealing materials and correct alignment with the system pipes are key to avoiding leaks and ensuring effective operation.

4. Can the 32mm check valve be used for industrial applications?

Yes, the valvula check 32mm Sodimac is suitable for a variety of applications, including industrial systems. It is ideal for systems where fluid backflow could cause damage or inefficiencies. For high-pressure or high-temperature conditions, ensure the valve material is appropriate (such as stainless steel for durability).

5. How can I maintain my 32mm check valve?

Regular maintenance includes inspecting the valve for any signs of wear, corrosion, or debris buildup. It’s also crucial to clean the valve and test its functionality periodically to ensure it opens and closes without any issues.

6. Where can I buy a valvula check 32mm Sodimac?

You can purchase the valvula check 32mm Sodimac directly from Sodimac’s online store or retail locations, which provide a wide range of plumbing and fluid control products.

Unlock the latest news and updates on Magazine Format